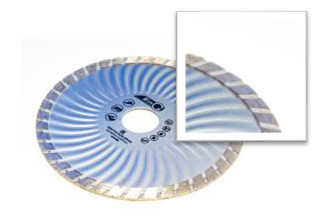

Алмазные круги TM RinG представлены рядом линеек отрезных кругов от 115 до 450мм для ручных машин, шовнарезчиков и стационарных машин.

В зависимости от конфигурации круга, круги предназначены для резки большинства строительных материалов — бетонов, железобетона, кирпича, брусчатки, шлакоблоков, дорожных бордюров, цементнопесчаной черепицы и других абразивных материалов.

Виды:

Плитка

Плитка

Круги для резки:

– Керамической плитки

– Мрамора

Турбо

Универсальные круги для резки:

– бетона

– кирпича

– черепиц

Турбоволна

Благодаря

дополнительным

ребрам охлаждения,

обладает большой

стойкостью при резке

твердых

материалов

Сегмент

Оптимальное решение

для резки

– армир. бетона

– мрамора, гранита

– прочих материалов

Турбосегмент

Круги для резки

широго ассортимента

– армир. бетона

– мрамора, гранита

– прочих материлов

Под заказ готовы поставить круги отрезные диаметром до 1400мм, а также трубчатые алмазные сверла диаметром от 20 до 250мм с напайными или сварными рабочими сегментами.

Контакты для заказа:

+7(910) 320- 40-40

+7(4722) 20-08-08

office@ringabraziv.ru

Адрес: Россия, г. Белгород, ул. Рабочая 14, литер Б6, оф. 3

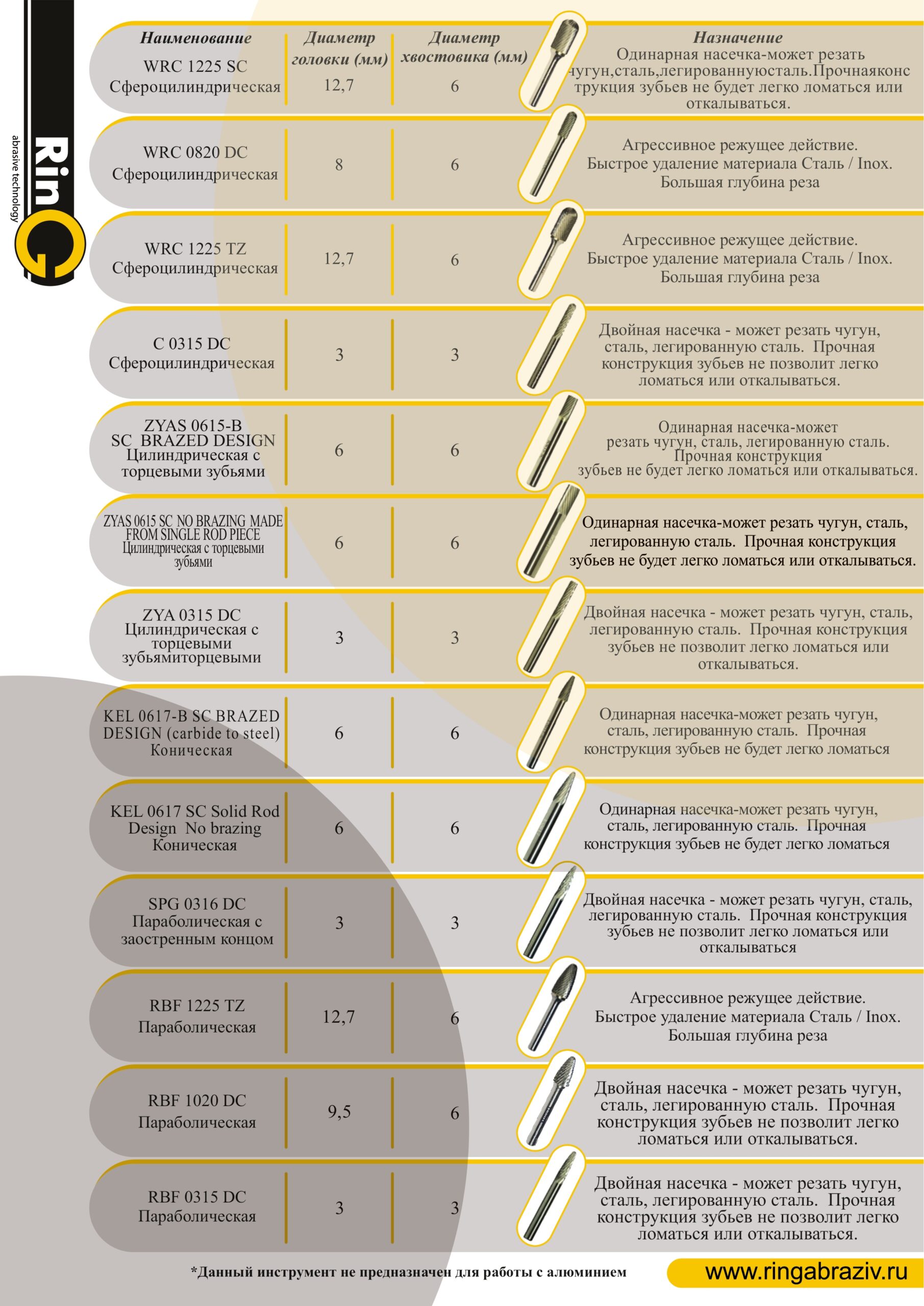

Борфрезы металлорежущий инструмент, представляет собой штифт с твердосплавной головкой, который применяют для обработки разных материалов – сталь, титан, чугун, цветные металлы, графит, стекло и пластик. Борфрезы бывают самых разнообразных видов, какой именно конфигурации будет такая фреза, зависит от сферы ее применения.

Контакты для заказа:

+7(910) 320- 40-40

+7(4722) 20-08-08

office@ringabraziv.ru

Адрес: Россия, г. Белгород, ул. Рабочая 14, литер Б6, оф. 3

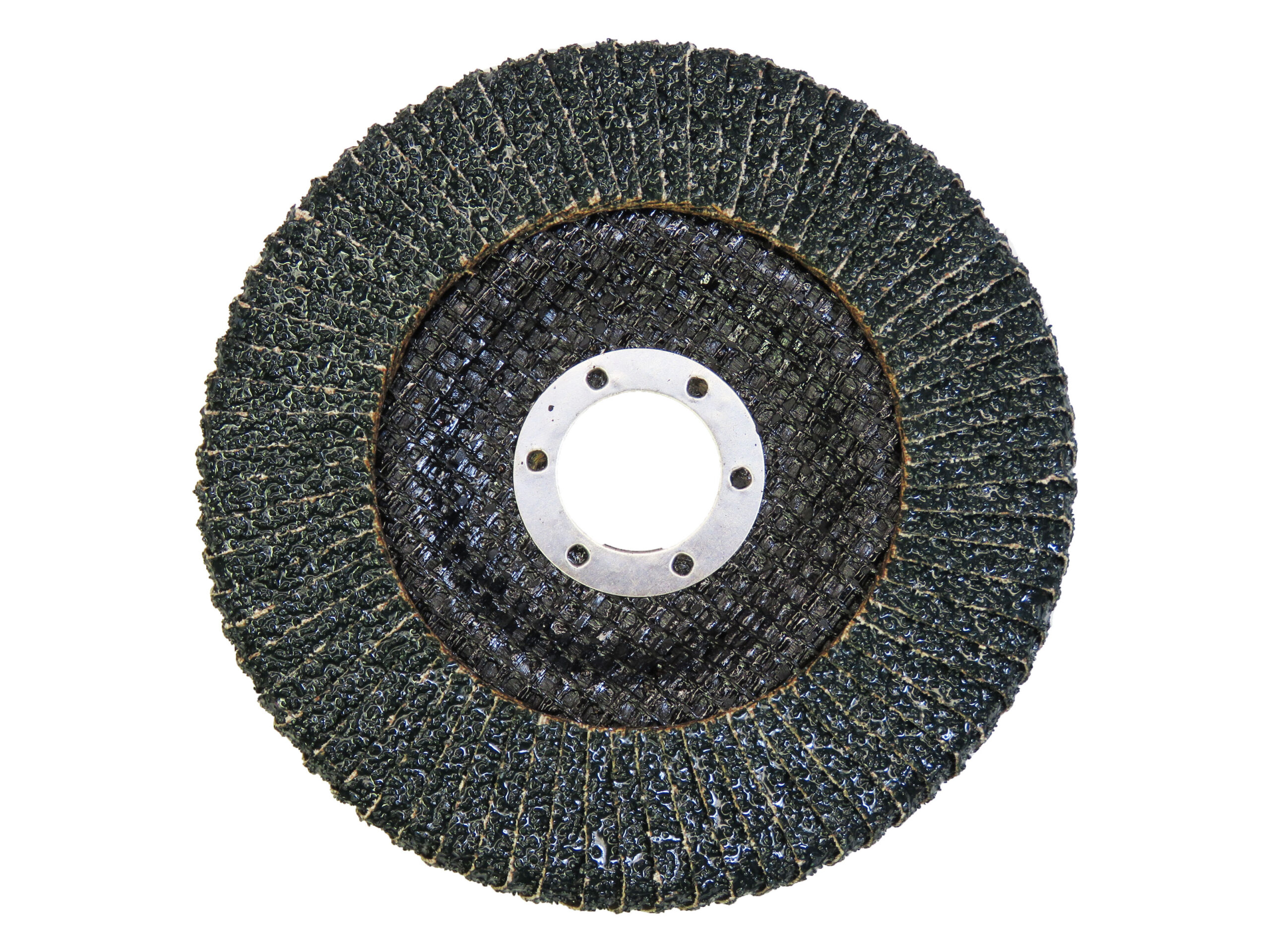

В данном разделе представлены:

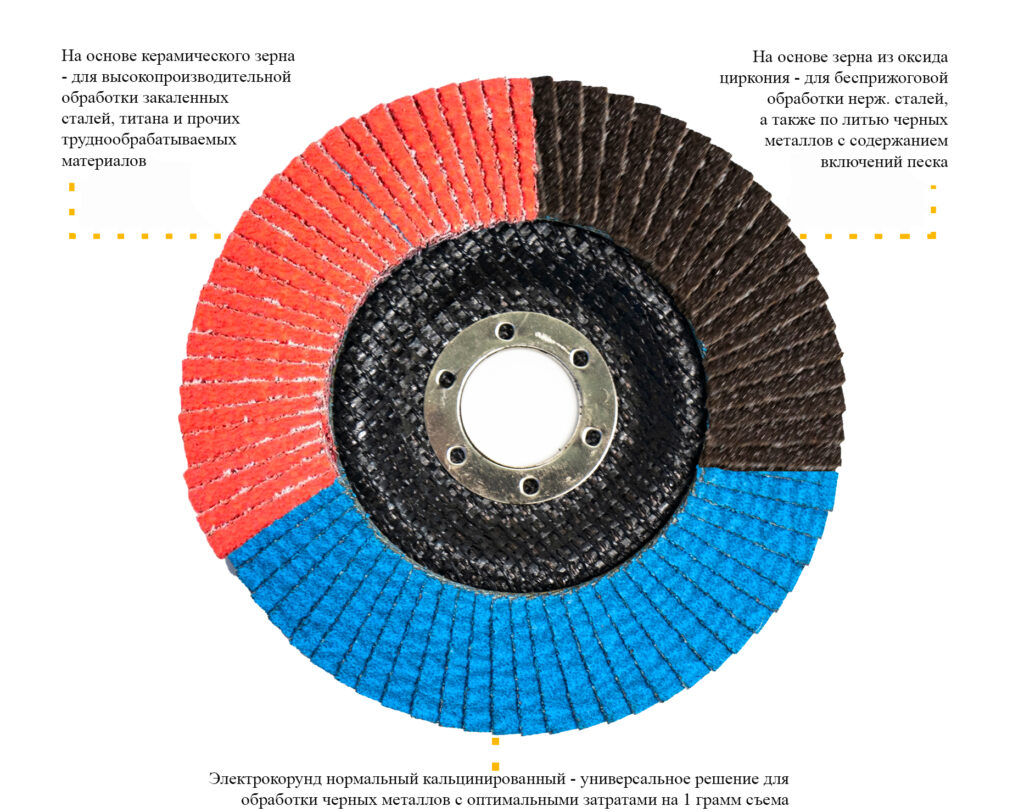

- Круги лепестковые торцевые на базе электрокорунда нормального, циркониевого и керамического зерна;

Лепестковые торцевые круги RinG представлены в трех линейках материа

ла шкурки

Круги лепестковые торцевые существенно превосходят армированные зачистные круги в операциях зачистки, где важным требованием является не только высокий съем металла, а и качество обработанной поверхности. Благодаря применению шлифовальной шкурки исключительно промышленного уровня, КЛТ марки RinG обеспечивают высокую производительность обработки и долгий срок службы круга.

Круги лепестковые торцевые существенно превосходят армированные зачистные круги в операциях зачистки, где важным требованием является не только высокий съем металла, а и качество обработанной поверхности. Благодаря применению шлифовальной шкурки исключительно промышленного уровня, КЛТ марки RinG обеспечивают высокую производительность обработки и долгий срок службы круга.

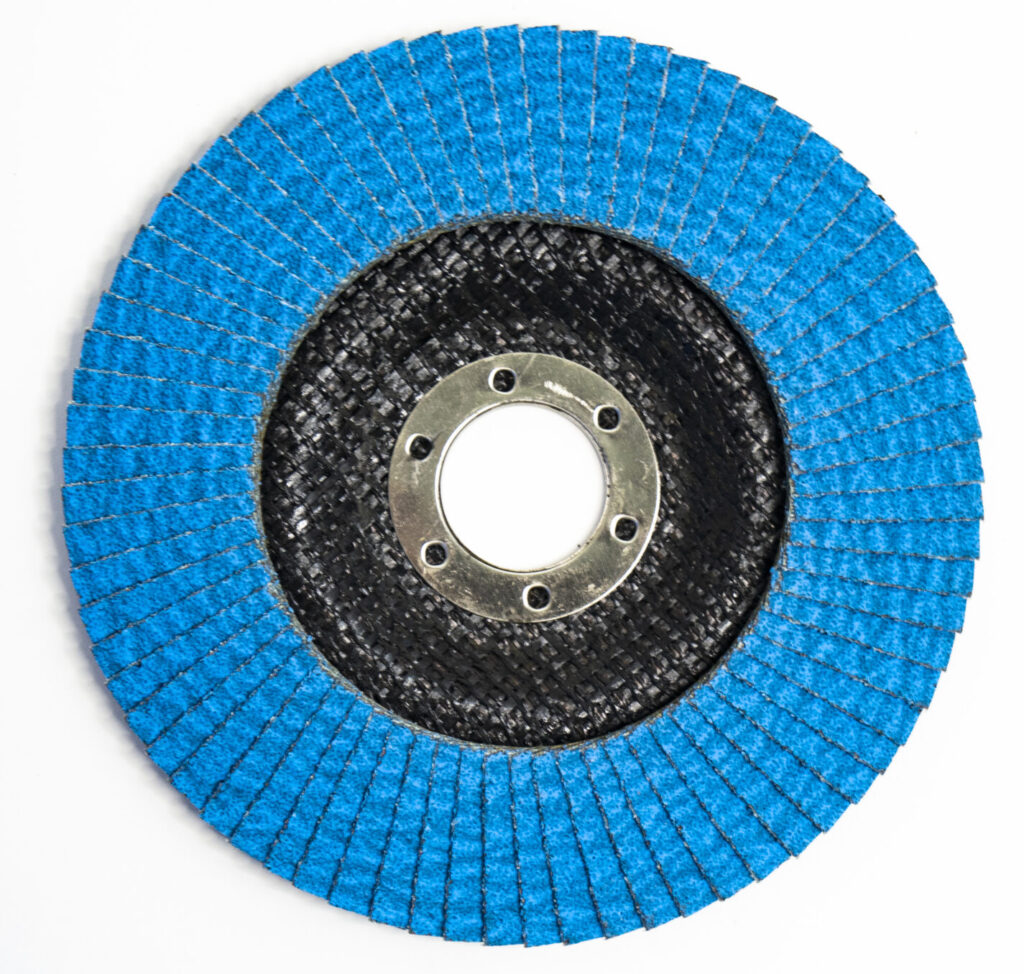

Серия КЛТ на основе циркониевой шлифовальной шкурки (содержание ZrO2 100%) ориентирована на самые тяжелые условия обработки. Оксид циркония благодаря большей прочности зерна обеспечивает в 2-5 раз более длительный срок службы инструмента и способен работать при усилиях прижима до 10 раз выше, чем круги на базе электрокорунда обычного. Оптимальное решение для обработки нержавеющей стали без образования прижогов.

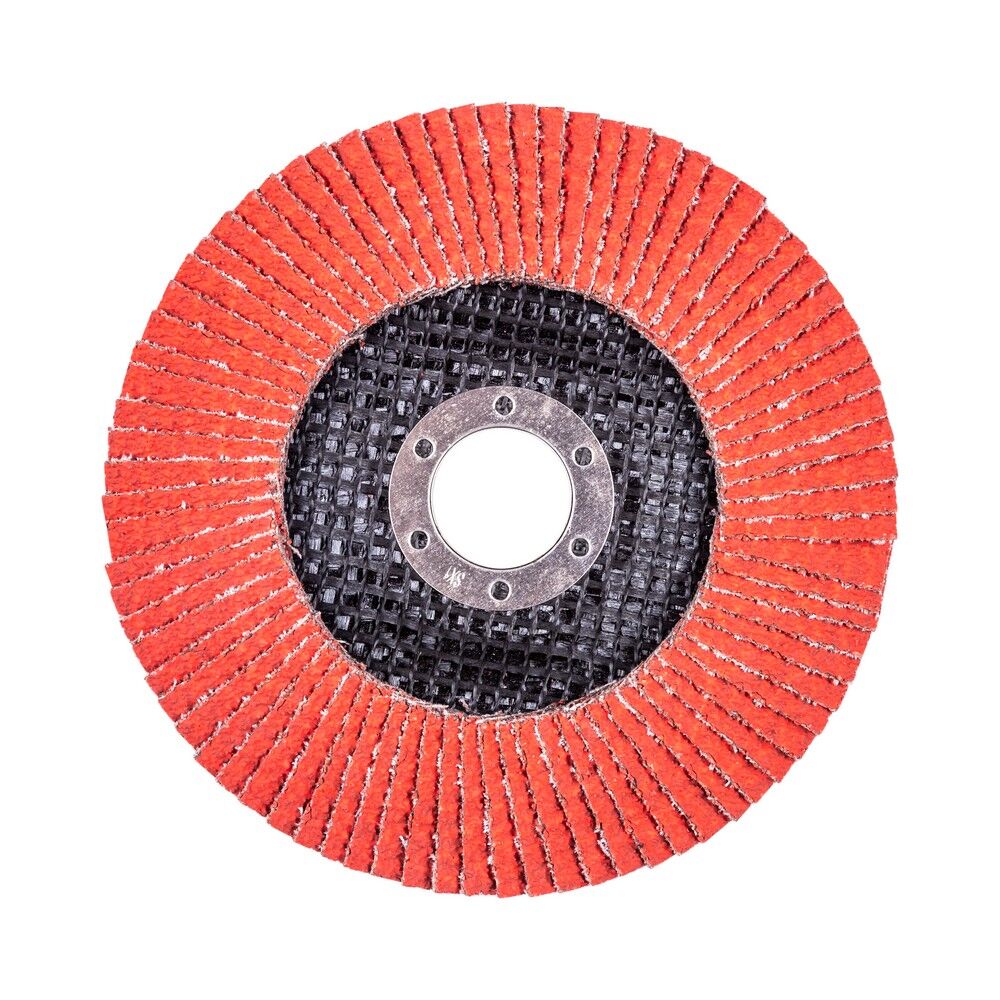

Серия КЛТ RinG на базе шкурки с керамическим зерном является наиболее эффективной при обработке с большими съемами материала. Благодаря агрессивному зерну со свойствами самозатачивания, достигается в 3-5 раз большая производительность в единицу времени, в сравнении с другими типами зерна. Рекомендуется прежде всего для обработки закаленных и нержавеющих сталей и титана.

2. Диски самозацепные;

Характеристики:

- Диаметр 125 мм, 150 мм

- Закаленный корунд

- Имеется зернистость Р40-Р1200

- Самозахватная высокопрочная основа

- Антистатические свойства

1. Стойкость к разрыву

2. Комфорт и гибкость

3. Обеспечивает однородные риски

4. Быстрая и легкая смена диска

5. Продолжительный срок службы Extra life

3. Ленты шлифовальные на базе различных типов зерен в зависимости от сферы применения.

Контакты для заказа:

+7(910) 320- 40-40

+7(4722) 20-08-08

office@ringabraziv.ru

Адрес: Россия, г. Белгород, ул. Рабочая 14, литер Б6, оф. 3

Ассортимент головок представлен прежде всего материалами 14А, 92А и 25А, как на керамической, так и на бакелитовой связках.

Предназначены для работы в прямых ручных шлифовальных машинах при обработке штампов, пресс-форм, сварных конструкций, литых деталей. Могут использоваться на стационарных металлообрабатывающих станках (например, для внутренней шлифовки).

Шлифовальные материалы

ЭЛЕКТРОКОРУНД НОРМАЛЬНЫЙ

ЭЛЕКТРОКОРУНД БЕЛЫЙ

ЭЛЕКТРОКОРУНД ХРОМИСТЫЙ РОЗОВЫЙ

ЭЛЕКТРОКОРУНД ХРОМИСТЫЙ РУБИНОВЫЙ. ЭЛЕКТРОКОРУНД ХРОМТИТАНИСТЫЙ

СПЕЧЕННЫЙ (КЕРАМИЧЕСКИЙ, ЗОЛЬ-ГЕЛЕВЫЙ) КОРУНД

КАРБИД КРЕМНИЯ ЗЕЛЕНЫЙ

КАРБИД КРЕМНИЯ ЧЕРНЫЙ

Контакты для заказа:

+7(910) 320- 40-40

+7(4722) 20-08-08

office@ringabraziv.ru

Адрес: Россия, г. Белгород, ул. Рабочая 14, литер Б6, оф. 3

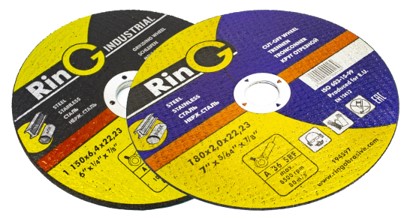

Ассортимент армированных кругов ТМ RinG включает в себя отрезные круги от 115 до 1250мм и зачистные круги от 115х6 до 230х10мм и представлен двумя линейками:

Линейка абразивных кругов RinG INDUSTRIAL® предназначена для работ с максимальной нагрузкой в промышленных условиях. Основная сфера применения:

- судостроительные,

- мостостроительные заводы,

- заводы металлоконструкций и литейные производства.

Отличается высокой прочностью и стойкостью инструмента. Особенно рекомендуется для использования на высокомощных электро и пневмошлифмашинах.

Виды:

Линейка RinG® является оптимальным и универсальным решением для применения, как в бытовых условиях, так и на промышленных предприятиях.

Абразивный инструмент ТМ RinG на бакелитовой связке выпускается из материалов марки 14А и 54С зернистостями F12-F150 твердостью М-ВТ в типоразмерах:

Абразивный инструмент ТМ RinG на бакелитовой связке выпускается из материалов марки 14А и 54С зернистостями F12-F150 твердостью М-ВТ в типоразмерах:

- различных типов кругов (1, 2, 11, 36, 40) диаметром от 125 до 900мм;

- различных типов сегментов (5С, 6С, 9С);

- Рабочая скорость инструмента – от 25 до 50 м/с.

Абразивный отрезной круг (диск) TM RinG, предназначен для холодной (теплой, горячей) резки сортового проката

Абразивный отрезной круг (диск) TM RinG, предназначен для холодной (теплой, горячей) резки сортового проката

Круги высокопроизводительной резки проката, с высоким содержанием циркониевого зерна для высокой стойкости и качественного реза. Точная спецификация кругов подбирается исходя из комбинации марок стали, профиля проката, мощности станка, температуры проката (холодный, теплый, горячий) и требований заказчика по качеству.

Контакты для заказа:

+7(910) 320- 40-40

+7(4722) 20-08-08

office@ringabraziv.ru

Адрес: Россия, г. Белгород, ул. Рабочая 14, литер Б6, оф. 3

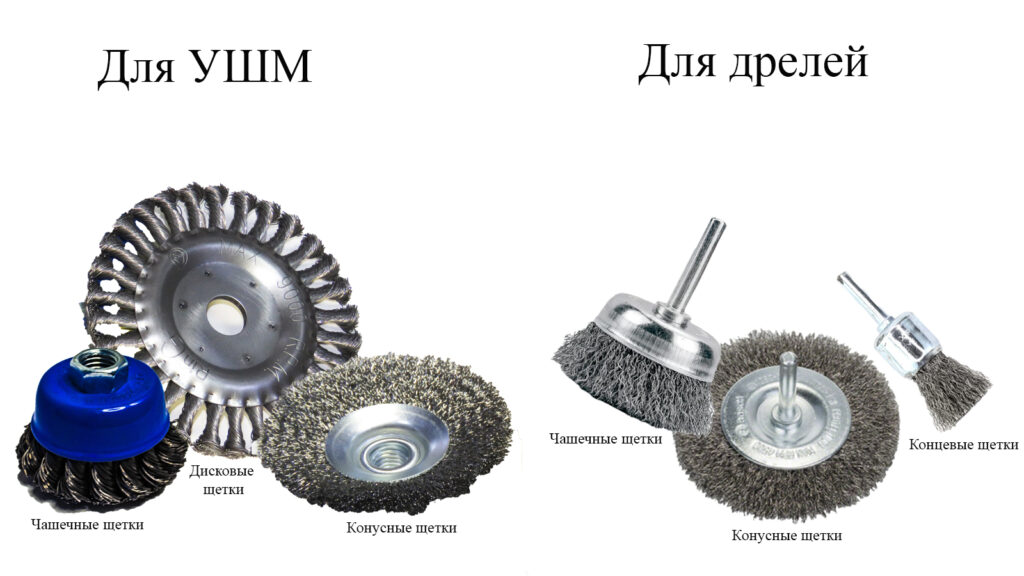

Стальными проволочными щетками могут выполняться самые различные работы: снятие заусенцев, удаление окалины и ржавчины, зачистка, удаление лакокрасочных покрытий.

Благодаря гибкости и эластичности, щетки точно повторяют контуры обрабатываемых деталей. Гибкость щеток зависит от толщины и длины стальной проволоки. Для оптимального эффекта обработки щетки должны работать только кончиками щетины. Производятся с гофрированной или плетеной проволокой.

Щетки в плетеном исполнении имеют более долгий срок службы, чем щетки в гофрированном исполнении и рассчитаны на экстремальные нагрузки и грубую силовую обработку зачищаемой поверхности.

Виды:

Применение:

Щетки для ручных шлифмашин из плетенной проволоки:

Для интенсивной очистки древесины, краски и металла. Идеальны для удаления ржавчины, зачистки сварных швов и зачистных работ с большим объемом обработки поверхности.

Щетки для ручных шлифмашин из гофрированной проволоки:

Для легкой / средней очистки древесины, краски и металла. Идеально подходят для легкого удаления ржавчины, обработки поверхности и удаления заусенцев.

Щетки для дрелей из гофрированной проволоки:

Для общей очистки древесины, краски и металла. Подходят для легкого удаления ржавчины и заусенцев. Хвостовик 6 мм подходит для использования с большинством электродрелей.

Контакты для заказа:

+7(910) 320- 40-40

+7(4722) 20-08-08

office@ringabraziv.ru

Адрес: Россия, г. Белгород, ул. Рабочая 14, литер Б6, оф. 3

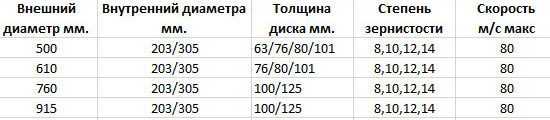

Шлифовальный круг горячего прессования TM RinG, предназначен для высокопроизводительной зачистки слитков и проката легированных марок стали в производственных условиях металлургических предприятий.

Практическое применение:

1. Шлифование под высоким давлением;

2. Удаление твердой оксидной корки в процессе производства стали (слябов, заготовок) и при изготовлении цилиндров;

3.Устранение локальных дефектов материала: серия 200, серия 300, серия 400, дуплекс;

Характеристики кругов горячего прессования

1. Высокая плотность, пористость < 2%

2. Более высокая температура + более высокое давление при изготовлении шлифовального круга

3. Дополнительное армирование (стеклоткань, сколы стекловолокна, армирующие кольца) для большей безопасности

4. Рабочая скорость до 80 м/с

5. Высокое давление в процессе шлифования

Достоинства:

1. Повышенная производительность в МРР/ч

2. Большая долговечность

3. Снижение затрат на шлифование

4. Повышенная устойчивость к различным нагрузкам

5. Специально разработаны для удовлетворения конкретных прикладных требований заказчиков

Контакты для заказа:

+7(910) 320- 40-40

+7(4722) 20-08-08

office@ringabraziv.ru

Адрес: Россия, г. Белгород, ул. Рабочая 14, литер Б6, оф. 3

Войлочные круги– это инструменты, используемые в различных областях, таких как шлифовка, полировка и обработка поверхностей. Они представляют собой круги из войлока или других волокнистых материалов и могут быть установлены на шлифовальных или полировальных машинах.

В зависимости от применения, войлочные круги могут использоваться для:

– Полировки: Они помогают добиться блестящей поверхности на металле, дереве или пластике.

–Шлифовки: Войлочные круги могут использоваться для удаления неровностей

и подготовки поверхностей к дальнейшей обработке.

– Чистки: Они могут эффективно удалять загрязнения с разных поверхностей

Войлочные круги бывают разных размеров, форм и жесткости, что позволяет использовать их в различных сферах, включая мебельное производство, автомобильную промышленность и ювелирное дело.

Контакты для заказа:

+7(910) 320- 40-40

+7(4722) 20-08-08

office@ringabraziv.ru

Адрес: Россия, г. Белгород, ул. Рабочая 14, литер Б6, оф. 3

Круг лепестковый торцевой с загнутыми лепестками– специально разработан для работы на угловых и тавровых сварных швах. Лепестки расположены на основной рабочей поверхности, торце и обратной стороне.

Технические характеристики:

Технические характеристики:

Диаметр – 125 мм

Посадочное отверстие – 22,23 мм

Материал – Циркониевый оксид алюминия Z

Зерно – P40

Обрабатываемые материалы – Сталь, нержавеющая сталь (INOX).

Контакты для заказа:

+7(910) 320- 40-40

+7(4722) 20-08-08

office@ringabraziv.ru

Адрес: Россия, г. Белгород, ул. Рабочая 14, литер Б6, оф. 3

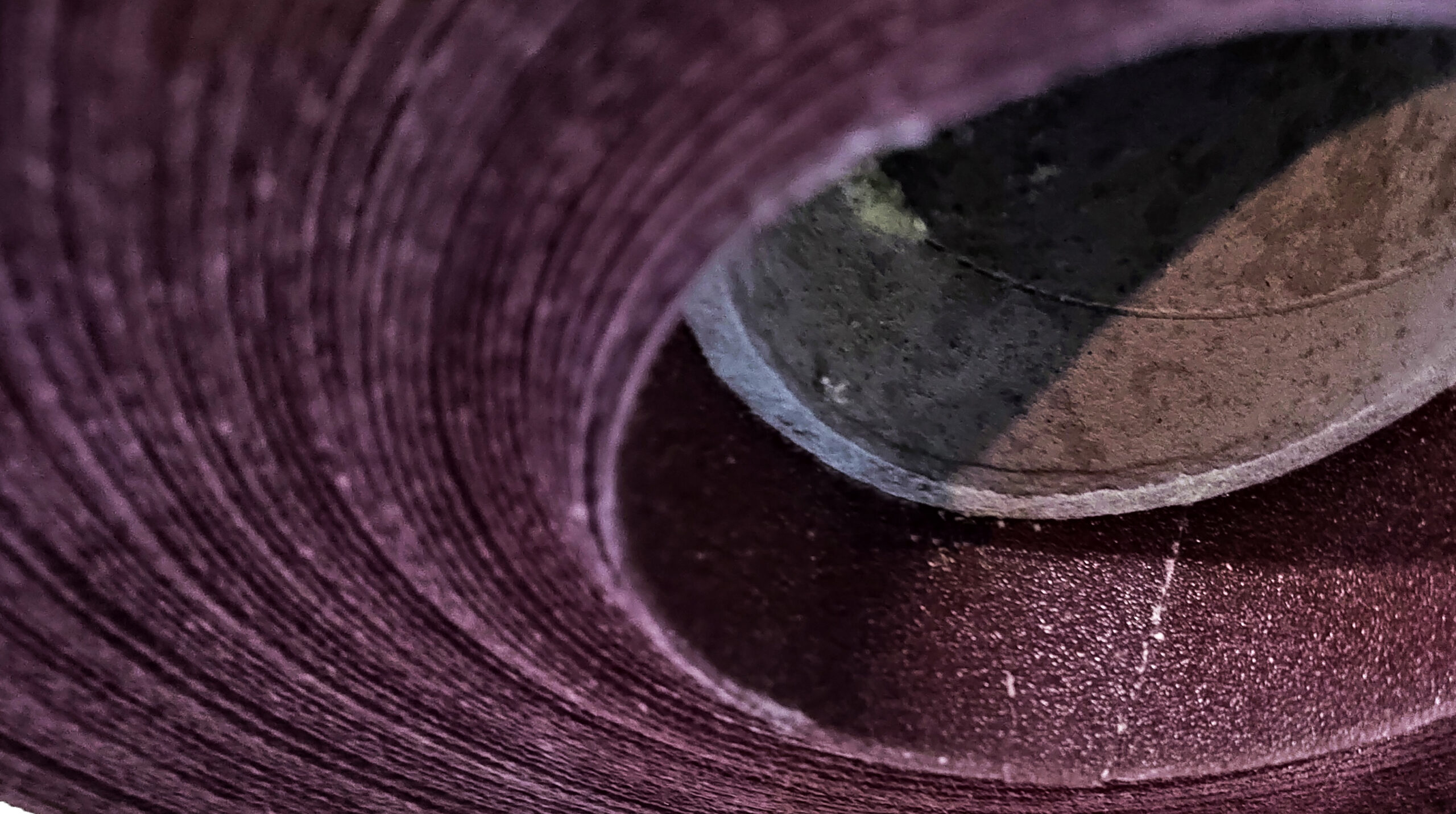

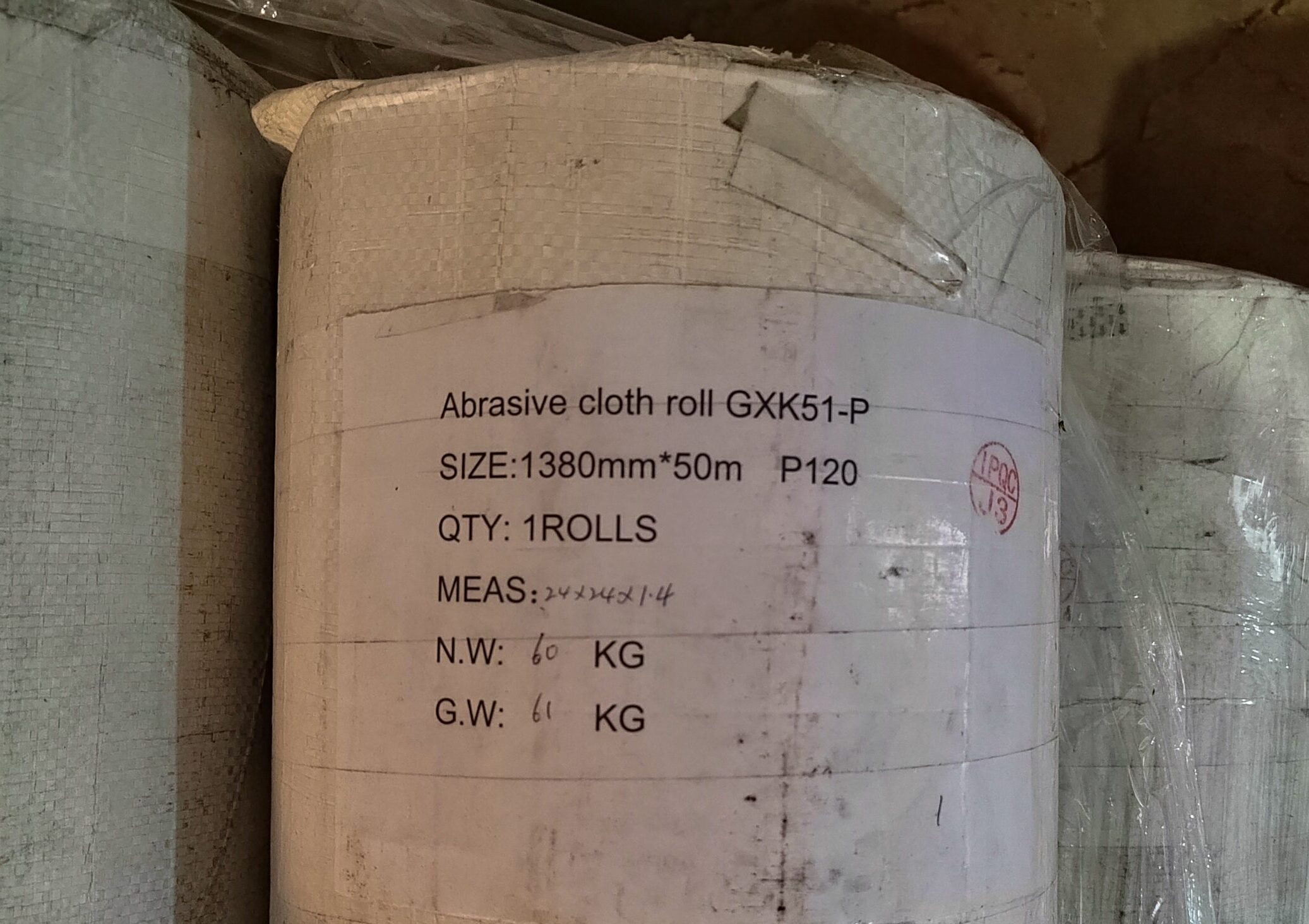

Шлифшкурка в рулонах размером 1380х50 mm может использоваться для различных шлифовальных работ, включая обработку древесины, металла и других материалов. Обычно такие рулоны подходят для электродрилей, шлифовальных машин или ручных шлифовальных инструментов.

При выборе шлифшкурки важно обратить внимание на зернистость (грубость) абразивного материала, так как она влияет на качество шлифовки. Чем ниже число зернистости, тем более грубое и агрессивное действие у шлифшкурки, и наоборот.

У нас Вы можете приобрести:

31013 ШКУРКА ШЛИФОВАЛЬНАЯ НА ТКАНЕВОЙ ОСНОВЕ GXK51-P P40 1380mm*50mm

31014 ШКУРКА ШЛИФОВАЛЬНАЯ НА ТКАНЕВОЙ ОСНОВЕ GXK51-P P80 1380mm*50mm

31015 ШКУРКА ШЛИФОВАЛЬНАЯ НА ТКАНЕВОЙ ОСНОВЕ GXK51-P P100 1380mm*50mm

31016 ШКУРКА ШЛИФОВАЛЬНАЯ НА ТКАНЕВОЙ ОСНОВЕ GXK51-P P120 1380mm*50mm

Контакты для заказа:

+7(910) 320- 40-40

+7(4722) 20-08-08

office@ringabraziv.ru

Адрес: Россия, г. Белгород, ул. Рабочая 14, литер Б6, оф. 3

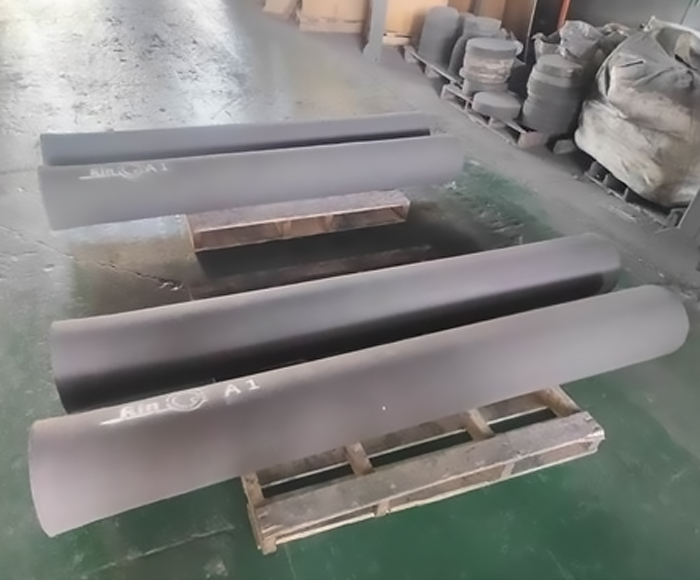

Графитовые тигли, изготовленные по технологии изостатического прессования, объединяют в себе высокую стойкость к окислению и механическую прочность и обеспечивают высокую стойкость к химическим реагентам, используемых для плавки алюминия и его сплавов.

Графитовые тигли идеально подходят для плавки и выдержки алюминия в газовых печах и печах сопротивления, также они идеально подходят для плавки цинка и цинковых сплавов.

У нас Вы можете приобрести:

30969 ТИГЕЛЬ HN420

31034 ТИГЕЛЬ ГРАФИТОВЫЙ HU250

31035 ТИГЕЛЬ ГРАФИТОВЫЙ HU300

31036 ТИГЕЛЬ ГРАФИТОВЫЙ HU350

Контакты для заказа:

+7(910) 320- 40-40

+7(4722) 20-08-08

office@ringabraziv.ru

Адрес: Россия, г. Белгород, ул. Рабочая 14, литер Б6, оф. 3

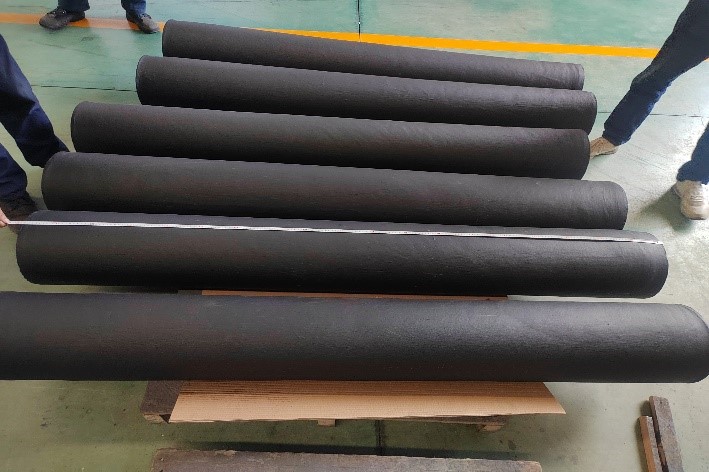

Муфель – огнеупорное изделие на основе графита в виде полой трубки. Применяется в муфельных печах для возгонки цинка и его паров при температуре 1100-1450 °C. Муфеля устанавливаются в печь, после чего внутрь них загружается цинк, подвергаемый нагреву. Происходит плавление и закипание цинка, его пары устраняются из печи для улавливания, после чего происходит новая загрузка металла. Муфель выполняет функцию передачи тепла металлу и канализирование устранения паров металла.

У нас Вы можете приобрести:

31032 МУФЕЛЬ ГРАФИТОВЫЙ HRT 1900×250

30946 МУФЕЛЬ HRT 1900×240

Контакты для заказа:

+7(910) 320- 40-40

+7(4722) 20-08-08

office@ringabraziv.ru

Адрес: Россия, г. Белгород, ул. Рабочая 14, литер Б6, оф. 3